By Bruce Petty

For better looking HO Scale Freight Cars

One thing model railroaders do well is collect bits of material that someday might useful for future model building projects. Yes, I am as guilty for sure, but this is one of my better finds and think my fellow modelers would might like to know about.

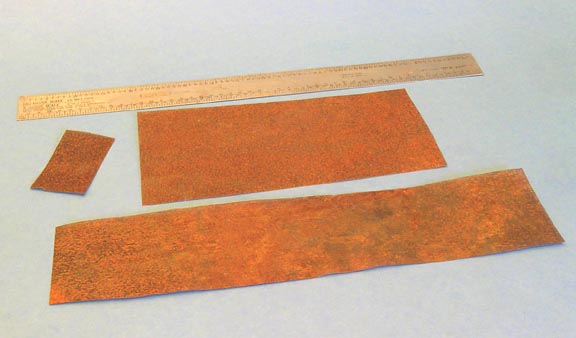

While out rail fanning, I found a discarded TV set that had its picture tube (CRT) smashed. On closer inspection of inside of the broken CRT, there was a sheet of thin perforated steel that set the height and width inside the tube. This perforated steel had very small slotted holes and figure this metal would be good for something. The TV tube must have been broken for some time as the perforated steel was covered with a thin coating of rust. I was thinking, “great metal for my junk yard!”

See Safety Note at bottom of page.

I carry sheet metal sheers along with me on outings just in case I find any rusted tin cans to cut up for use in my model scrap yard. (For reference see Model Railroader Magazine, Oct. 06 issue, page 66. “Build an Operating Scrap Yard.”) I work on this model project while waiting for trains to show up, that is if I’m lucky. Anyway, I’ll go home with something even if its not a train picture.

I was able to cut many sections out of the perforated metal and bring them home. Not knowing enough about the insides of TV tubes, I couldn’t say if all tubes have the same type of perforated steel, but if I see another broken one, its worth a look anyway. (Warning) Don’t try and break a CRT, they implode and you could get cut from flying glass. Best to use already only broken CRT’s. Talk to your local landfill operator.

Some of my favorite freight cars are the old metal ones made by Varney. The only problem is the reefers and box cars have really thick plastic roof walks. I’ve been meaning to change the roof walks to the nicer metal etched ones, but each cost of over $7.00 per car, the replacement gets somewhat expensive for a small detail improvement such as this.

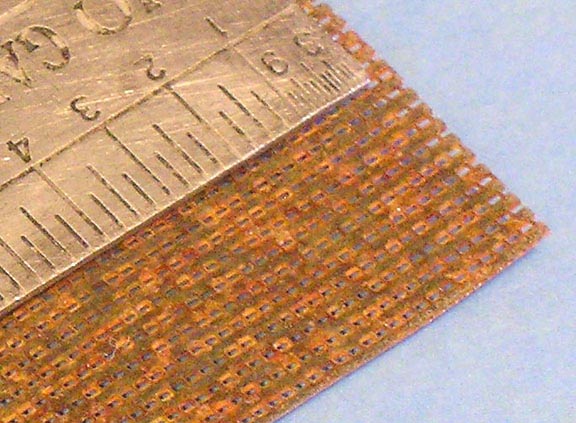

Small scissors are used to cut strips of perforated steel using the slotted holes the as a guide. I added one slotted width on each side of the roof walk width to be folded over. Cut the length using the old plastic roof walk as a guide. A small file is used to dress the edges. A straight edge is used to fold in the perforated area next to the outside edges to give the the thin steel a little support and correct roof walk thickness.

To mount the roof walk onto the car, I used strip wood close to the inside width of the roof walk and the cut to the length of the car. A black felt tip marker is used to cover all the light wood color. Use Duro Quick Gel to mount the wood to inside the of the U shaped roof walk, centering the wood strip for the overhang of the ends of the roof walk equally. I used a small amount of Duro Quick Gel on each rip of the car, then mount the roof walk, hold in place for a minute until the glue is set.

This perforated steel with natural rusting color looked so much like a prototype roof walk, I didn’t bother painting it. Maybe I will on some of the other cars. The left over pieces was sent to my scrap yard just as it would be done on the prototype.

SAFETY NOTE: I can not advise people to go looking for discarded or broken television tubes, and do NOT break one. However, I look for old broken tube that has been out in the weather for years and use heavy duty gloves and metal cutters to carefully to remove the screen material. Cathode ray tubes have coatings of phosphorus, an extremely poisonous material if any gets into a skin abrasion will cause a health problem.