by Bruce Petty

Building an HO Scale Model

Building the Sheller Feed Company model in HO scale has been an nostalgic project from my youth.

Here the local has finished its days work and is about to begin the trip home.

Back in 1963 when I was issued my first California drivers license, I was able drive and explore along the Southern Pacific Railroad in the San Fernando Valley. One industry I found interesting to photograph then was the Sheller Feed Company located near the city of San Fernando. This industrial structure set along SP’s Valley Line heading towards Bakersfield via the Teachappi route. A few diaries and ranches were holdouts at the northwestern end of the Valley as the housing boom approached.

The Sheller Feed Company was built at the time when the San Fernando Valley was mostly farmland. By the 1960s, Sheller was the last feed supplier in the Valley served by railroad. Most business along the SP’s, Valley, Coast Line and the Burbank Branch were lumber yards supplying the needs of contractors building new homes and apartment buildings.

Purina was and still is the largest producer of bulk livestock feeds. The feed mill would make up the mix’s for livestock, so a number of different commodities delivered by rail, shelled corn, barely oats and soybeans. Without going into details of these how all these commodities were mixed into different feeds, they were sold in bulk or by the sack.

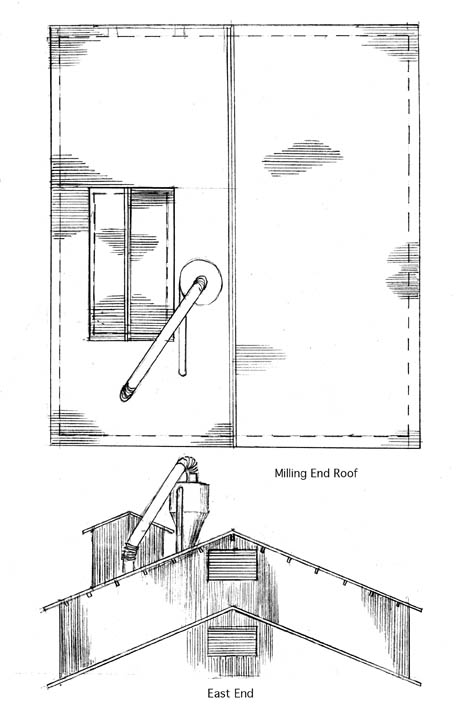

Box cars had a protective paper inside their sliding doors and were spotted next to the taller structure with the receiving chute. The chute can be seen in the picture at the bottom-center of the taller processing structure. This receiving chute would drop down at an angle to meet an open box car door, the inside paper would be cut so the commodity would free fall down the chute for a conveyer to lift and stored in separate bins. After the commodity finished free falling from the box car door, the rest had to be hand shoveled to the ends of the box car. This was hard labor, but at the time labor was cheep.

A feed supplier also received fertilizer and other farm necessities by box car unloading through the to sliding door to be stored inside the warehouse for resale.

Modeling the Structure

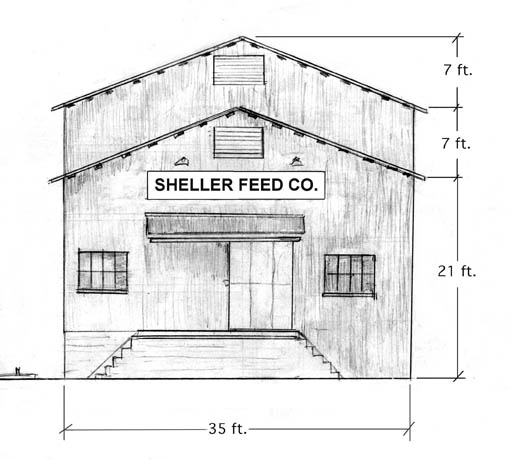

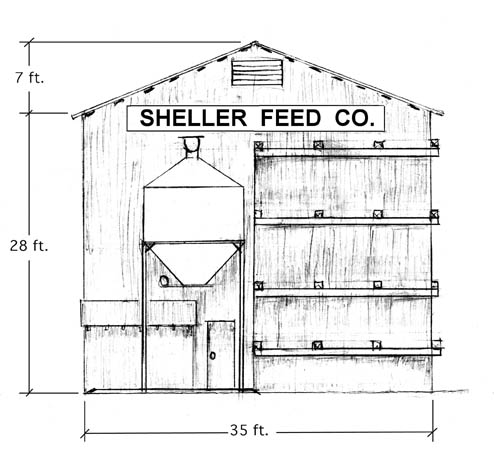

It only took forty years to build this structure from my old photos, think I always knew that it would make an interesting industry for my layout. But I had to do bit of selective compression so this large structure would fit on the layout. Both the length and width of the structure were reduced a bit, however the height was kept the same. The plans seen here are for the compressed model form.

I didn’t model the back side of the structure, because it wouldn’t have be seen on my shelf layout, nor did I take any pictures of that side back then. I did add several sliding doors to the warehouse areas back side like the sliding door seen on the front. So your guess is as good as mine.

Progress photo of the milling end of the HO model.

The finished warehouse end. The taller milling structure and the warehouse are modeled as seperate units and placed together, this makes it easier to paint them later. I built up the windows using Evergreen styrene, 1″X 2″scale lumber.

I airbrushed the structure with Floquil silver then weathered with water based Latex dark gray and brown.

The truck loading bin was built as a single unit instead of the double as seen in the prototype photo, this because of the model is built narrower than the prototype. I’ve also added the bin filling conveyor and small conveyor parts laying on the ground as seen in the prototype photo. The bin, conveyor and small parts were weathered with an airbrush using rust color over silver.

The “Sheller Feed Co.” sign was designed following its prototype photo.

You may copy this sign and reduce it to 8 scale feet wide. As the size of the sign is reduced using a Photoshop type program, keep the resolution in proportion so the DPI to go high. Doing this will allow your printer will produce a high quality print.

I printed the sign on regular paper, cut out and mounted it to the side of the warehouse using a little Glue-Stick on the corners.

This is really a easy way to make signs for your other structures.

The Purina Feed Truck

The feed truck was built up using an HO metal model already lettered for Purina. I removed the truck bed that came with the model and built my own. This type of bed is typical to feed trucks that are loaded under a bin and unloaded by the use of a conveyor that is operated by a power take-off on the transmission. I added a piston to pull up the back gate so the conveyor can unload. Still need to add a few little details like tail lights, mud flaps and mirrors.